Yes, supply chain management is also used in service businesses and helps them to provide timely and quality services to customers.

- 021-91034194

- Info@pishco.ir

- Tehran, Sa'adat Abad

Home » What is supply chain management (SCM)?

Every business that produces and offers a specific product needs a system that can fully coordinate these processes and give them coherence and order. In the past, businesses were structured differently and competition was not as intense, so the need to utilize advanced technologies was not strongly felt.

Today, even a small negligence can lead to the downfall of a business, and the full use of all available facilities paves the way for the success of the organization. One of the effective strategies in this direction is supply chain management. But what is the supply chain and what stages does its implementation include?

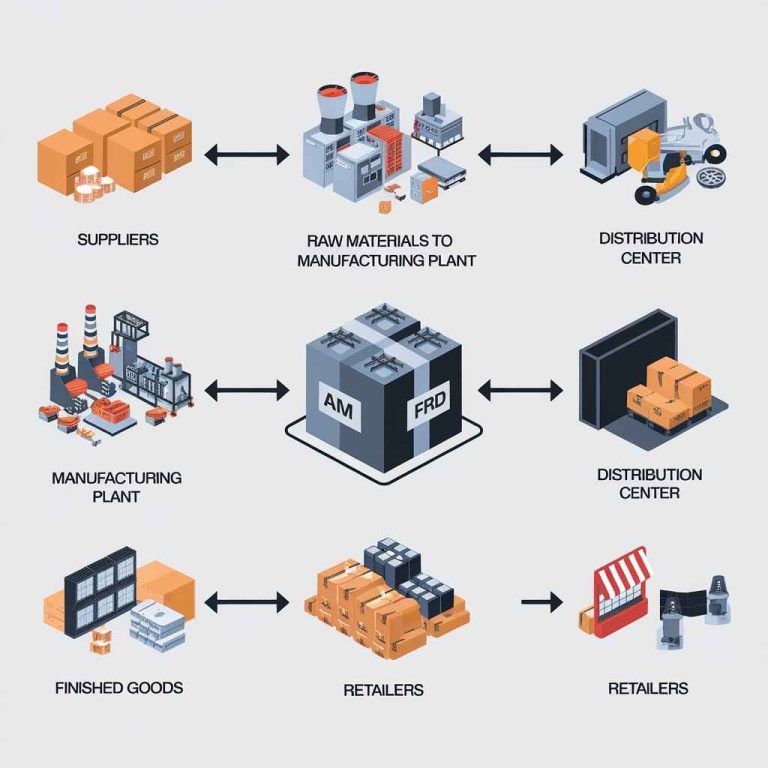

Supply chain refers to a set of processes through which a service or product is produced and reaches the customer. Meanwhile, there are many roles, each of which has a specific task. From manufacturers of goods or services, suppliers, logistics service providers and warehouse keepers to retailers who are responsible for the final supply to the customer, everyone has a role in this supply chain process.

Every business must identify its supply chain management process well and be able to cooperate effectively with all actors of this process. Otherwise, there is a possibility of disrupting processes and even business failure.

To produce a certain product and provide a certain service by an organization, a defined process must be followed. This process, which is known as the supply chain, includes the supply of raw materials from supply sources, production of goods, delivery to the customer and provision of after-sales services. Also, all processes that help to improve or facilitate this chain are known as supply chain management (SCM).

Supply chain management is considered as a way to strengthen the competitive advantages of businesses by simplifying the operations of supplying goods and increasing customer satisfaction. In short, this management includes a network of people, organizations, resources, technologies and expertise that cooperate in an integrated way to produce, distribute and sell products.

The structure of the supply chain generally begins with the procurement of raw materials from manufacturers and ends with the supply of the final product to customers in retail stores. Each stage of this chain creates certain costs for businesses. Therefore, optimization of the supply chain can lead to the reduction of waste of resources and reduction of additional costs.

The supply chain is activated when a manufacturer receives an order from a customer. Hence, its main functions include product development, marketing, sales, production, distribution networks, finance and customer service. The entities involved in this chain include manufacturers, sellers, warehouses, transport companies, distribution centers and capillary distribution and retailers.

Supply chain management is based on four main elements: integration, operations, purchasing and distribution. Each of these elements plays a vital role in the supply chain and must be done properly to ensure business success:

Integration: One of the key parts of supply chain management is the establishment of effective communication and close cooperation between all parties involved in a business strategy. This cooperation reduces errors and saves costs. Integrating different departments helps to combine different expertise and form more efficient teams. This process helps the managers to better manage the overall operations and identify the weak points of the organization easily.

Operations: The operations department is responsible for monitoring the work of employees and ensuring the progress of the plans. Managers must continuously evaluate processes to ensure that all stages of the supply chain are progressing properly. Also, with these evaluations, efficient parts are better identified and manpower can be used in a more optimal way.

Purchasing: Before getting raw materials from suppliers, you should determine what materials you need, how much and from which suppliers? What will be the quality and cost? These analyzes are not only limited to raw materials, but also include equipment, machinery, and even hiring employees. If there is a deficiency in any of these areas, the production process will be delayed and this issue may seriously affect the credit of the business. On the other hand, buying too much may exceed the organization’s capacity and budget and create new problems.

Distribution: Delivery of goods to the customer is the last stage of the supply chain. Whether this delivery is through store shelves or through direct shipping, it requires careful planning to achieve customer satisfaction. At this stage, and especially in the logistics sector, using a suitable software can be very efficient and improve the delivery process.

Supply chain serves as the backbone of today’s commercial organizations and businesses. Supply chain management strategies give more value to the customer than other strategies and methods in a business, and this can have a significant impact on the growth and development of the organization. Here we discuss the main objectives of supply chain management:

Increase efficiency

Improving efficiency means reducing any waste in processes. These wastes are not only limited to physical waste; Rather, time, material, cost, and even customer loss may also be lost during the production and distribution process. Supply chain management minimizes waste by optimizing production, inventory, transportation, and identifying improvement opportunities. Although the process itself is not easy, the end result is worth the effort.

Quality improvement

Another goal of supply chain management is to improve the quality of products through compliance with quality principles and legal standards. These standards are defined based on customer needs. In order to improve quality, it is necessary that strict standards are defined and used in the production process from the beginning. These standards include compliance with safety and ethical principles.

Optimizing logistics and transportation

Contrary to what some people think, supply chain management is not only limited to logistics, but logistics is one of its areas of focus. This department includes up-to-date systems for material handling and software that helps suppliers, manufacturers, retailers and wholesalers track product status. SCM ensures that the supply chain process is carried out effectively.

Reduce costs

One of the main goals of supply chain management is to reduce costs in different stages of supply. The high speed of the supply chain cycle in a successful system makes goods move faster and maintenance costs are reduced. In addition, costs related to purchase, production and delivery will also be saved.

Increase customer satisfaction

As mentioned, customer satisfaction is now the first priority in supply chain management. This satisfaction is achieved in two ways:

Improve distribution

Supply chain management plays a significant role in improving the distribution process. By coordinating transportation channels and warehouses, costs are reduced and distribution speed is increased.

Increasing coordination in the chain

Supply chain management aims to create greater coordination between the stakeholders of a business. This strategy allows employees, customers and suppliers to communicate effectively with the business. Managers can guide employees better and they can also interact with their employers when necessary. These measures lead to increased coordination in the entire supply chain process.

In general, there are two types of supply chain: closed loop supply chain and open loop supply chain, which we will explain below:

Closed-Loop Supply Chain – CLSC

In this model, materials and resources are returned to the production cycle and reused, instead of being discarded as waste. The main goal of this type of chain is to create a stable system with the least amount of waste. Food industry, fast food and beverage manufacturers usually use this type of chain.

Opened-Loop Supply Chain – OLSC

In this type of supply chain, used products are not returned to the original company and are recycled and used by other companies. In this model, recycled materials are converted into other products. For example, old Nike shoes are used as new fibers. The main difference between this chain and the closed loop type is in returning the products to the main company or using them in other companies.

Continuous Flow Supply Chain Management

This model is one of the most traditional and stable supply chain management methods, which is suitable for industries with constant demand. In this method, similar goods continuously flow between the manufacturer, distributor and customer.

Fast Chain Management

This model is used for products with a short life cycle. For maximum productivity and sales of these types of products, special processes are needed.

Efficient supply chain management

This model is suitable for industries with intense competition and its goal is to increase efficiency and optimal production. Any inefficiency in this chain can have devastating effects on the entire system. Challenges such as labor shortages, raw material shortages or production interruptions can give opportunities to competitors.

Agile supply chain management

This method is suitable for specialized items that require more care and attention. In this model, technology is used to transport and distribute these goods, and due to the high costs of transportation, a balance must be maintained in the volume of products to be economical.

Custom-Configured Supply Chain Management

This model is a combination of the agile model and the continuous flow model and is designed in such a way that it is possible to change and adjust according to specific needs at different stages of the chain.

Flexible supply chain management

This model helps businesses to manage demand in irregular or unstable conditions. Using this method, businesses can respond to demand in booming seasons and adapt to conditions in low demand seasons. To implement this method, appropriate logistics and procurement software is needed.

Supply chain management strives to reduce shortages and keep costs down. This work is not only limited to the preparation and purchase of inventory; Rather, supply chain managers should monitor and direct the entire supply chain process and logistics operations in a way that increases efficiency and reduces the organization’s costs in the supply chain.

Improving the productivity and efficiency of the supply chain ultimately affects the final product. In the supply chain management (SCM) system, the supply chain manager coordinates all steps of this process, which includes five main parts.

planning

To achieve the best results in SCM, the supply chain management process must begin with proper planning to coordinate supply and customer demand. This planning includes predicting the future needs of customers and adapting production to it. It also relates to the raw resources required at each stage, equipment capacity, limitations and manpower. Many large companies rely on ERP software to collect information and prepare applications.

Sourcing

The effectiveness of SCM processes strongly depends on strong relationships with suppliers. Sourcing involves working with vendors to provide the raw materials needed in the production process. Organizations need to ensure that raw materials are in line with production needs, costs are in line with the market, and suppliers have the ability to meet unexpected needs.

production

Production is the heart of the supply chain management process. At this stage, raw materials are converted into finished products. This process includes activities such as assembly, testing, inspection and packaging. Companies should watch out for factors such as waste and production problems that may cause deviations from the original plans.

delivery

After producing and selling products, organizations must deliver their products to customers. Distribution plays an important role in shaping the brand image; Because it is the first interaction that the customer has with the product. In an efficient SCM, companies use diverse logistics systems and delivery channels to ensure timely and safe delivery of products.

return

The last step in supply chain management includes product support and return of goods from customers. This process, also known as reverse logistics, allows companies to receive and reimburse returned goods. Analyzing the reasons for returning goods is also an important part of this step, which helps to identify and fix problems so that they do not repeat in the future.

Let’s explore the key roles in a supply chain, as part of supply chain management (SCM) involves directing and controlling these roles.

Chief Procurement Officer (CPO)

This supply chain executive role is responsible for sourcing, procurement and supply chain management for a business. The Chief Procurement Officer’s main focus is on cost management and he ensures that costs remain under control. He is always looking for ways to reduce costs and is also responsible for ensuring that the organization’s purchasing processes comply with internal and external laws, including government regulations and internal company policies.

Chief Logistics Officer (CLO)

The chief logistics manager is responsible for overseeing the transfer of goods or services provided by the company. This manager ensures that products are moved on time and correctly. Some of the challenges of this role include the shortage of truck drivers and managing transport tariffs in certain situations.

Supply chain manager

The supply chain manager plays a vital role in various aspects such as product manufacturing, inventory management, exporting goods to international markets, and collaborating with suppliers and foreign partners. He is responsible for evaluating suppliers and negotiating contracts with vendors. Supply chain managers are often referred to as executives and have operational responsibilities. This role includes formulating policies, overseeing daily workflows, and controlling worker activities.

25 years ago, one of the main reasons companies turned to creating global supply chains was to reduce costs in other countries. In general, adjustment of transportation costs caused by distant productions became possible easily. However, cost management is always evolving; Because wages are rising in low-cost countries. Also, recent advances in technology and robotics have made it possible for factories to continue operating with much smaller workforces, and local companies have become serious competitors in many industries.

One of the key advantages of the global supply chain has been the possibility of dispersing patents and manufacturing sites around the world. This allows companies to declare profits in countries with lower corporate taxes. However, many of these methods have encountered challenges. In 2016, the European Commission ordered Apple to pay €13 billion in back taxes to Ireland, ruling that Apple’s tax deal with Ireland constituted illegal state aid. Margaret Vestager, the EU’s antitrust chief, recently launched an investigation into Amazon’s tax practices in Europe. Google and other tech companies are also under EU scrutiny.

To improve your supply chain using technology, you need to use new and advanced technologies that can help you collect, process, analyze and share data and information.

To identify and manage supply chain risks, methods such as risk analysis, risk prevention, risk reduction, risk transfer and risk acceptance should be used.

Yes, supply chain management is also used in service businesses and helps them to provide timely and quality services to customers.

لطفا فرم زیر را به دقت پر کنید تا مشاورین ما در اسرع وقت با شما تماس حاصل فرمایند.

Please fill out the form below carefully so that our consultants will contact you as soon as possible.