- 021-91034194

- Info@pishco.ir

- Tehran, Sa'adat Abad

Home » Method of recovery and purification of burnt oil

Various technologies are used to recycle and purify burnt oil. With the aim of renovating, purifying and recovering used oils, these industries have designed, built and operated various equipment to produce a product that can withstand the harsh conditions of high temperature and extreme pressure inside the engine and at the same time help to preserve the environment. . Considering the required performance characteristics and the working environment of motor oils, which are contaminated with all kinds of physical and chemical pollution such as water, solid particles, gas and liquid, the recycling process of these oils is associated with certain challenges and complications.

To refine crude oil, we have to go through several steps to obtain pure oil. These steps include:

Oil de-stepping: In this step, the gums in the oil are removed. This process is carried out in two ways: degradation with water and degradation with phosphoric acid and citric acid. In the first method, oil is mixed with water to separate the gum with the help of centrifugal force. But some solutes such as magnesium and calcium are not separated with water and need to use acid. In the second method, phosphoric acid is added to the oil at a rate of one to two tenths of a percent and heated at a temperature of 80 to 150 degrees Celsius. By vigorous stirring, the remaining gums are removed.

Neutralization of free fatty acid: First, the amount of free fatty acid in the oil is measured and then the amount of profit necessary for neutralization is calculated. By adding soda solution to the oil, the fatty acids are converted into insoluble soaps and separated from the oil. This step may be repeated for complete cleaning. After that, the oil is washed with hot water and the remaining soaps are removed by a centrifuge. Then the oil is dried under vacuum conditions and transferred to the next stage of purification.

Oil decolorization: In this step, the colored substances remaining in the oil are absorbed and removed by the decolorizing soil, which is a kind of hydrated aluminum silicate. The oil is mixed with the paint remover soil under vacuum conditions and after the appropriate time, filtration is done to separate the paint remover soil and other impurities from the oil. This process also removes metals from the oil that affect its shelf life.

Oil deodorization: In this step, volatile compounds and unpleasant odors that may have been created due to oxidation or the presence of natural substances in the oil are removed from the oil. The oil is purified with steam at high temperature and under vacuum conditions to remove these volatile compounds from it. After smoking, citric acid is added to the oil to remove the remaining metals, and finally, antioxidants are added to prevent oxidation. After the last stage of filtration, the oil is packaged.

Using advanced equipment and experienced experts, oil refining factories provide optimal conditions for oil refining according to today’s standards. Sellers and consumers should also maintain the quality of the oil by observing the maintenance principles so that the result of the producer’s effort is maintained.

A number of spent oil purification and recycling techniques can be categorized as follows:

In the acid purification method, the used oil is first introduced into the distillation tank after initial dewatering in the preheater. During the distillation process, diesel and light substances in the oil are separated by reaching a temperature of 370 degrees Celsius, and finally, the thermal cracking process ends with the oxidation of the additive compounds remaining in the oil.

Then, the boiled oil is cooled down to 40°C using heat exchangers and transferred to acid washing tanks. At this stage, the boiled oil is mixed with concentrated sulfuric acid at a rate of 10% by weight and washed. After 10 to 12 hours, the acid sludge removal operation, which makes up about 15% of the oil’s weight, begins.

The acid oil is then neutralized with lime water and mixed with colored soil in the tilling unit and heated to a temperature of 160 degrees Celsius. Finally, using a filter press, the base oil is separated from the filter cake and recovered. This method also has disadvantages; including the large volume of acid sludge, strong and unpleasant smell, harmful vapors of sulfuric acid, the difficulty of controlling the acidity and color of the produced base oil, and the heat generation of the acid sulfonation reaction with oil aromatic hydrocarbons.

In the alkaline recycling method, the used oil is first dehydrated by increasing the temperature to about 120 degrees Celsius. Then, by passing through the heat exchangers, its temperature is reduced to less than 45 degrees, and extraction and washing operations are performed with an aqueous solution of calcium carbonate and soda on the dehydrated oil. After 10 to 12 hours, the settled sludge is separated from the oil phase, which constitutes about 20% by weight of the total burned oil.

After sludge removal, the oil is transferred to the distillation unit. At this stage, the burnt oil is heated up to 350 degrees Celsius while mixing with the color-removing soil, and during the distillation process, light cuts and diesel are separated from the base oil. After passing through the filtration stage, the base oil is purified and stored in tanks. Although this method has low costs for machinery and consumables, the level of technology used in it is low and a large amount of waste sludge is produced. Also, the base oil produced by this method does not have a good quality in terms of appearance, color and smell.

This recycling method is very simple and does not require advanced technology or complex equipment. But it has many disadvantages; including the production of significant pollution caused by residual acid sludge that damages the environment. In addition, low technical quality, high recycling costs and long process time make this method unsuitable. Using acid and alkali along with soiling for oil refining is an old method that has become obsolete in many countries of the world, but it is still used in some oil refining units in Iran.

This oil purification method does not require the use of acid. Other steps are similar to the previous method and due to the simplicity of the process, it is suitable for low capacity units. Soil consumption in this method is high and its efficiency is relatively low. Disposing of a large volume of contaminated clay brings environmental challenges. Also, this process depends on a specific type of clay that may not be readily available in all areas.

In this method, which has been used so far only in a limited number of active purification units in the country, after the initial dewatering and sludge removal of the used oil in standing cylindrical tanks with a conical bottom, the oil is again separated into three phases of water and sludge through separator devices. And the oil is divided. At this stage, the oil coming out of the separator is significantly sludged.

Then the sludged oil is heated to a temperature of about 150 degrees centigrade by passing through the preheater heat exchanger and transferred to the distillation tower. This tower, with a suitable design and the return of condensed vapors, allows the separation of oils in several stages. During the distillation operation under a relative vacuum pressure of about 250 mm Hg and a temperature of 400 °C, the distilled oil, which has a high flash point, enters the shell-and-tube heat exchangers and its temperature is reduced to 35 °C. Then, the cooled oil is transferred to acid washing and solvent extraction tanks.

At this stage, the distilled oil is first washed with a mixture of sulfuric acid and acetic acid at a ratio of 2% by weight to remove sulfur compounds and unpleasant odors in the oil. Finally, the oil is extracted with a mineral solvent and the remaining residues and colored compounds are separated from it.

After extraction, the mineral solvent can be recovered and reused from the extraction phase using a simple distillation method. After solvent recycling and oil separation, in the next steps, the oil is transferred to the dyeing unit to modify its final color and smell. In the tank mixers, the oil is heated up to a temperature of 180 degrees Celsius after mixing with the dye-removing soil and injecting steam, so that the base oil is separated and stored through the purification process in the filtration section.

In this method, according to the operation in the distillation tower, it is possible to separate different cuts of oil such as SN150, SN300 and SN500 from the bottom of the tower. Also, the base oil produced in this method has a high flash point and viscosity, which is suitable for the production of the desired products in the plan. In terms of color, smell, appearance and other standard factors, these oils can compete with primary refined oils.

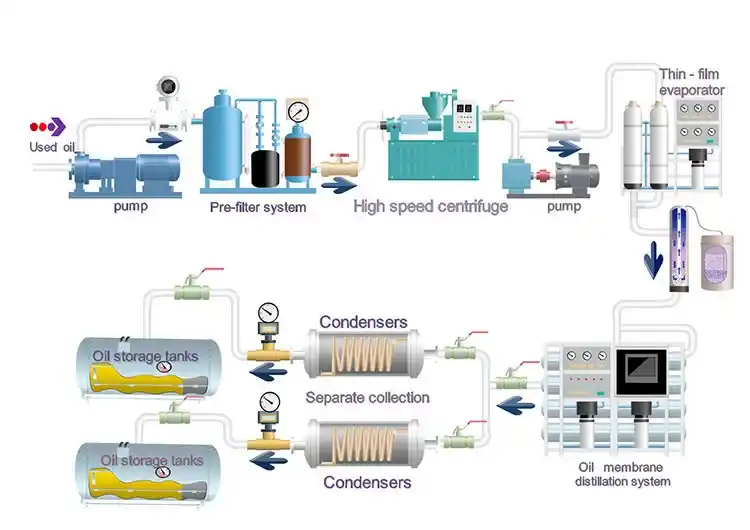

In this process, the burnt oil is first pre-refined and then subjected to distillation to separate water and light hydrocarbons. In the distillation method, the oil is evaporated by heating, and after that, the oil base products are separated by condensation at different levels. The molecular distillation separation process takes place under vacuum conditions using thin film and low controlled temperature, without adding any chemicals (such as acid and soil).

The base oil produced from this process is in accordance with the standards of the American Petroleum Institute (API) in groups 1 and 2 or the European ACEA standard and as a suitable feed for formulating and formulating all kinds of industrial, engine, turbine, hydraulic, gear and grease oils. is used.

Refinement steps

In this method, the oil first passes through primary filters to separate its unsaturated impurities. Then, the oil is transferred to a low-temperature vacuum distillation tower to separate light substances including water, diesel and gasoline from it. Next, the oil is fed into high-vacuum thin-film distillation reactors to separate heavier materials. In this step, the oil becomes a thin film on the hot surface, which is carried out by the brushes attached to the rotor.

This technique greatly increases the molecular free path and causes the oil to evaporate at low temperatures. At this stage, the oil fractions from SN 100 to SN 500 are partially evaporated and condensed. After this stage, the waste is separated from the oil with colored compounds and used as bituminous sludge in various industries. The output products of this process include base oil of groups 1 and 2, high quality industrial distillate fuel and bituminous waste that can be used in the production of polymer bitumen, asphalt and isogam.

It is worth noting that in this method, no additives including acid and soil are needed for color removal and purification, so this process, in addition to meeting environmental issues, also has high efficiency.

Extractive technologies based on vacuum distillation and chemical purification are processes in which the use of propane solvent at room temperature has replaced chemical purification in the initial stage. In this method, the burnt oil is first pre-treated with an alkaline solution including ammonium hydroxide or potassium hydroxide to neutralize its undesirable compounds.

After this step, the oil is mixed with a propane solvent that is well compatible with hydrocarbons and is able to remove metals and other contaminants from the oil. Solid particles, water and pollution in the separation tank are cleaned. The oil and propane mixture is then transferred to a set of heat exchangers to separate the propane and go to the flash separator. At this stage, propane is condensed with cold water and returned to the solvent tank for reuse.

In the purification process with propane solvent, oil is introduced into the extraction reactor with a certain percentage and due to the lightness of propane, it is vaporized in the upper part of the reactor. The insoluble oil remains at the bottom and is distilled separately to remove light hydrocarbons and residual propane.

Then, this oil is distilled under vacuum to separate the processes, and in the final stages of the hydrofinishing process, the recycled oil is obtained with the desired quality. The waste of this process can also be used as a raw material for asphalt production. One of the advantages of this method is the ability to recover solvent and produce oil with good quality. However, not all contamination can be completely removed. This system operates at high pressure and sealing and controlling its processes can sometimes be risky and expensive. For this reason, it is not usually used on a small economic scale due to the high cost of the equipment.

In this process, first the incoming raw materials are filtered to separate the solid materials from them. Then, the solution is combined and heated with hot hydrogen in a pressurized mixing column. The heated mixture is transferred to a flash separator and goes to the strainer with the flash separator liquid. Separated vapors and residual materials are purified in the upper part of the filter and strainer to remove dissolved metals through a catalytic reactor. After that, using the hydrofinishing process, desulfurization and dechlorination are performed. This process improves the chemical and physical properties of the produced oil compared to the input feed by saturating the aromatic substances and performing appropriate hydrocracking reactions.

The process conditions, including pressure, speed and hydrogen circulation rate in each unit, vary based on the quality of the incoming feed. In this method, the input oil is converted into a hydrocarbon product with a wide boiling range, which during the process are separated into neutral oil products with different viscosities and can be used for blending into lubricating oils. This method is able to recover more than 85% of input feed oil and obtain multiple outputs from it.

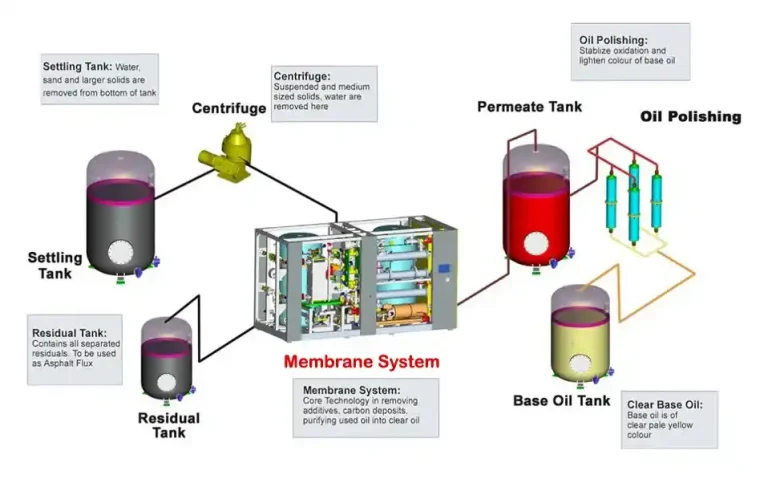

This purification technology is much cleaner and more energy efficient, and its process is designed based on ultrafiltration of burnt oil using efficient membranes and barriers containing activated carbon. In this method, water and large sediments are first separated by centrifuge at low temperatures, and then by pre-distillation, water and solvent are separated, and the oil is pre-treated with chemicals to improve quality.

The pre-refined oil is transferred to the separation column and at this stage its diesel is separated. The critical step of the ultrafiltration process is at high temperatures, where oil, polymer, and fine particles are separated through small-diameter tubular filters. Next, catalytic hydrotreating is done to improve the color of the final product and makes it possible to produce different types of oils by distillation under vacuum.

The recycling of burnt oil has many advantages, some of which are mentioned:

Environmental protection: Proper oil recycling prevents environmental pollution that can negatively affect public health, wildlife, and natural resources.

Conservation of natural resources: According to the EPA, approximately 380 million gallons of oil are recycled annually, helping to use this valuable resource more efficiently.

Energy saving: In the process of oil re-refining, about one-third less energy is needed than the methods of removing impurities from crude oil to achieve the desired quality of the lubricant. This means optimal management of energy costs.

Reduced costs for companies: Waste disposal costs can be high, but treating used oil is usually less expensive than disposing of it.

According to the definition of EPA, burnt oil refers to any oil obtained from crude oil or synthetic oils and as a result of consumption, it is contaminated with physical or chemical impurities. During normal use, impurities such as dirt, metal wear, water, or chemicals may mix with the oil, significantly reducing its performance over time. Finally, this used oil must be replaced with fresh or refined oil so that it can perform its duties properly.

لطفا فرم زیر را به دقت پر کنید تا مشاورین ما در اسرع وقت با شما تماس حاصل فرمایند.

Please fill out the form below carefully so that our consultants will contact you as soon as possible.