- 021-91034194

- Info@pishco.ir

- Tehran, Sa'adat Abad

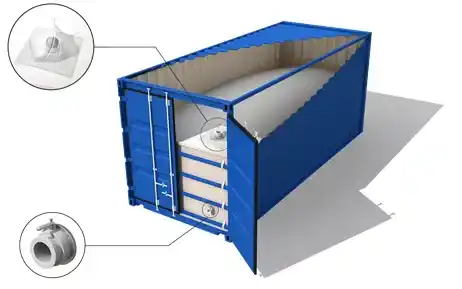

Flexibag or flexitank is a strong and thick type of bag that is used to carry non-corrosive and non-hazardous liquids in containers. The tolerable temperature for flexi tank is +70 degrees Celsius and its minimum tolerable temperature is -50 degrees Celsius.

Petro imen Sharif Company does this important thing by using containers and flexibags to transport the burnt oils used in the operation unit to all places.

The loading capacity of Flexi Tank varies depending on the density of the goods used. Below are the loading rates for several types of goods:

– Load glycerin: 20,000 liters in Flexi Tank – Load olive oil: 22,000 liters Flexi Bag – Load rogan palm: 21,000 liters Flexi Tank – Load plastic: 19,000 liters Flexi Tank – Load latex: 19,000 liters Flexi Bag

These flexi tanks and flexi bags are selected for optimal and safe transportation according to the type of goods and their density.

Flexi tanks are flexible tanks designed for storage and transportation of non-hazardous liquids in bulk. These versatile containers have multiple advantages that make them a popular choice for various industries. Let’s explore the types of goods that can be transported using a flexi tank:

– Edible oils: vegetable oils, cooking oils and other food liquids can be transported safely in flexi tanks and ensure their quality and freshness.

– Industrial oils: Lubricants, hydraulic fluids and other industrial oils are usually transported using these flexible tanks.

– Chemicals: non-hazardous chemicals such as glycerin, sorbitol, lactic acid and emulsifiers can be transported in a flexi tank.

– Base oils: Both automotive and transformer base oils find their way into flexi tanks for efficient transportation.

– Liquid sweeteners: Fructose, malt extract and other liquid sweeteners can be transported safely using flexi tanks.

– Beverages: Fruit juices, syrups and even wine and beer can be safely transported in these containers.

– Hydrocarbons: various hydrocarbon-based liquids are included in the scope of flexitank transportation.

Due to the flexibility and security they offer, these tanks are considered an ideal option for transporting various liquids on an industrial scale.

Flexibag loading involves several steps to ensure safe and efficient transportation of liquid cargo. Here is a simple overview of the process:

1 – Selection of a flexible tank: Select a suitable flexible tank based on a different type (including food, manufacturing or chemicals).

2 – Connection: Connection to the flexible tank: Connection to the flexible tank to connect to it.

Filling the flexi tank: pumping liquid into the flexi tank up to the desired capacity.

Close the valve: Close the inlet valve to prevent leakage.

3 – Equipment: Make use of suitable equipment to install the flexible tank in the container.

A tight fastener: It is important to have a container and be reassured by the tightness of the fastbandi.

4 – Loading and transporting: Loading and transporting a container with a flexi tank barge on the road to Darya, Rahhan or Avenue.

Reassurance in handling: appropriate weight distribution and reassurance in stability over the length of carrying and transporting.

5 – Clearing: destination: leaving a container in a container or the establishments of a destination.

Draining the flexi tank: opening the outlet valve to drain the liquid from the flexi tank.

Removing the Flexi Tank: Carefully remove the empty Flexi Tank.

6 – Push or use again: Push: Turn on the Flexi Tank and use it according to local regulations.

Reuse: Some flexi tanks are reusable; They can be cleaned and used for subsequent transport.

This comprehensive process for loading, transporting and unloading flexi tanks in various modes of transport ensures that liquid cargoes are carried out safely and with high efficiency.

Cost reduction: The most economical option for shipping and cleaning costs.

High capacity: up to 24,000 liters of liquid, without barrel weight and with a larger volume of goods.

Time and labor saving: simple and faster work than carrying with barrel or drum.

Zipper circumference diaper: Use of divisible materials in the Flexi Tank.

For export, the trailer goes to the factory’s container depot to load the container and then goes to the factory’s scales after placing the container on it.

After recording the empty weight, the fitting operation begins.

Fitting operation:

The steps of preparing the flexi inside the container for loading are called fitting.

Including:

Cleaning the container and removing any sharp edges and burrs that could cause the flexi to be punctured.

Installing retaining profiles that prevent the middle of the container from sagging.

Protective layers of the flexi that consist of a layer of cardboard on the wall and several layers of cardboard and Unolith on the bottom of the container.

Opening and spreading the flexi in the designated place

Installing the retaining door from which the flexi loading valve comes out and allows the door to be closed after loading.

Loading:

After the fitting operation, the flexi is ready for loading, which is sealed based on the capacity of the loaded flexi, and after issuing the bill of lading, it is sent to Shahid Rajaee Port.

لطفا فرم زیر را به دقت پر کنید تا مشاورین ما در اسرع وقت با شما تماس حاصل فرمایند.

Please fill out the form below carefully so that our consultants will contact you as soon as possible.